Speed lathes have come a long way in the manufacturing world, and have proven to be incredibly useful when it comes to deburring/lapping/sanding. However, like any machine, they can pose a safety risk if not used correctly or set up properly.

In fact, misusing industrial equipment can result in severe or fatal injuries. According to the Bureau of Labor Statistics, there were nearly 2.8 million nonfatal workplace injuries in 2017, with 395 thousand cases of injuries in manufacturing workplaces alone.

Manufacturing is an essential component of the way we live, but because of the high-speed machines and equipment manufacturers commonly use, it can also be a dangerous job if basic safety and machine set up protocol is not followed.

It’s critical to take preventative care and safety precautions when using a speed lathe to avoid injury or a broken machine. First, let’s understand what a speed lathe is, what to use it for, and how it came to be the “mother of all machines” it is today.

When To Use A Speed Lathe

Speed lathes are used to remove small amounts of unwanted material from a workpiece on a diameter. They have a long history, serving as one of the oldest machine tools that manufacturers use daily.

Most speed lathes are built for metallic materials (steel, aluminum, brass), but people use them for wood, plastic,glass and ceramic materials as well. There are a variety of ways that you could use a speed lathe, though they are generally for smaller, more detailed parts. Speed lathes are suitable for jewelry, connector pins, fittings, and for creating a multitude of mechanical parts. Generally speaking, if you need to refine or improve the surface texture or surface Ra in a specific area, speed lathes are ideal for the job.

Ensuring Safety With A Speed Lathe

Speed lathes play an enormous role in manufacturing. Without the invention of the Lathe, we would not be nearly as developed as we are today.

Although a standard manufacturing tool used in factories and workshops around the world, they are fast machines that can pose dangers to the users if they are not used correctly. Speed lathes are continually spinning and revolving pieces that could fly out from the device and injure yourself or surrounding people.

When working with a speed lathe, it’s best to know all there is about its preventative care, maintenance, and safety requirements.

Securely Set Up Your Lathe

Setting up your speed lathe starts with unboxing it – and since Overbeck’s machines weigh 64 pounds, you’ll need to use a hand truck or a team to lift it off the ground.

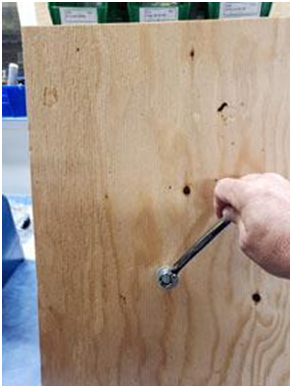

The machine is shipped with a wood shipping base attached, as pictured here:

Start by removing the foam strip from the top of the machine and the foam bundle containing the power cord and foot switch. Then, place a cardboard or foam sheet onto the bench and roll the machine onto it’s back so you can remove the single fastener that holds the wood sheet in place with a ½” wrench.

Now that the machine is void of the wood shipping base, roll the machine back onto its 5 rubber feet.

From there, make sure the machine is placed at least two inches back from the edge of your work surface. This gives you optimal room to work while minimizing the potential for tipping/snagging on passersby or the machine falling off the bench. It is also possible to bolt the machine to the work surface. Consult the Overbeck Machine Twister Owners manual found on the Overbeck Web Site.

Once you’ve situated the machine onto a workbench, take time to consider the ergonomics of your working environment.

In most working environments, the assumption is that the operator will be seated in a chair with a backrest. The seat-to-bench height relationship is important and starts with the feet. When seated, your feet should be flat on the floor, so adjust the seat height to make that possible. If the seat surface is too high, your feet will dangle bring on a loss of blood flow to the lower legs. Too low, and you will need to lift your foot up in order to depress the foot switch and also feel compacted on the chair.

Once proper seating height is obtained, adjust the workbench to a starting distance of 12” above the seat surface. Normally your seated to workbench height is about 31-1/2” high. A work bench with an adjustable height does make the ergonomic adjustments easy.

The time duration that you sit at your workstation should also be controlled, in that you should take a work break for stretching. Stand up from your chair and move around. Stretch or rotate your torso from side to side. Stay limber and avoid sitting for extended periods of time without taking a break to move the parts of your body that don’t move during your work task.

Preventative Care And Maintenance

The second aspect of safely using a speed lathe is to ensure that you properly maintain the machine. Failure to do so can shorten the working life of the machine.

The only consistent maintenance your speed lathe will require is regular lubrication and adjustments. Improper lubrication or no lubrication can cause excessive wear, leading to dangerous operating conditions. Conduct a functional check on the switches and mechanical function of the collet closer. Report any issues to your Supervisor or Manager. If issues are found, do not use the machine. Use proper Lock out/Tag out procedures so that others will not use a defective machine. Consult the Overbeck Machine Twister Owners Manual for more detailed information or call the factory at 1-831-425-5912 for exact lubrication points or procedures.

Dusty conditions can also be very hazardous to your speed lathe. It should be kept clean of grit and dirt. Overbeck Machine recommends that after each use, do a quick, brief cleaning so you don’t start the next day or next job with a dirty machine. Use a shop towel with a bit of Simple Green cleaner. Do not use the shop air hose to blow the machine off. This will drive abrasive grit into places you do not want abrasive grit.

Additionally, if your lathe is transported out of the shop, it should stay protected from any dust and extreme temperature conditions. In hot conditions, use care to avoid overheating the motor, and try to use slower speeds when in cold environments. Use of any liquid to aid in sanding or deburring is expressly not permitted. Also, modifications of your speed lathe or use of non factory parts may expose you to unsafe conditions or lead to failure of the machine.

Safety Requirements

Speed lathes should only be used by certified and qualified professionals to ensure safety.

This means that lathe operators must be trained, as they are accountable for following safe work practices while operating the machine. This is because lathes involve fast, rotating parts with flying material chips and dust. There’s also always a chance that other work going on in your general area can introduce flying parts or debris, so safety gear is essential.

Once you have an adequately trained lathe operator, ensure that these safety guidelines are met:

-

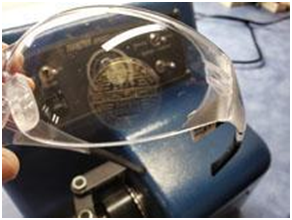

Always wear safety glasses or goggles that met ANSI Z87+ standard at a minimum.

-

Protect your hearing, use earplugs, muffs or the hearing protection mandated by your company or consult the OSHA regulations. NRR 32 dB protection is a minimum.

-

Protect your feet: Closed-toe anti-slip safety footwear. Consult OSHA footwear to prevent injury — ideally work boots

-

Close-fitting, protective clothing

-

Never wear leather or textile gloves. Use Medical or Mechanical latex gloves only

-

Remove rings, watches, and other jewelry

-

Roll sleeves up to your elbows

-

Tie long hair back into a ponytail, and pin it back to avoid catching.

-

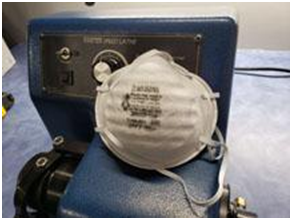

Protect your lungs from airborne particles with a mask with a minimum of N95

-

In all cases, proper PPE should be provided by your boss, superior or employer. Proper PPE only works when you use it. Use of Personal Protective Equipment is not a guarantee of safety and good health, but it is one of the best ways to protect yourself.

It’s important to note that defective equipment offers little protection, which is why it’s vital that lathe operators are trained when it comes to understanding how the machine works. In the case of an emergency or malfunction, all users should know where the emergency stop is. They must be easy to access, and all users should become familiar with emergency shutdown procedures.

Before starting the machine, you should check the Twister Speed Lathe for any missing or loose parts. If there are any mechanical or safety issues, this could pose a danger to the user.

When you’re ready for operation, take note of these general guidelines:

-

Never lean on the lathe

-

Never lay tools directly on the machine

-

Always use two hands when sanding the workplace

-

Handle other tools and equipment carefully

Also, be sure to remember important machine safeguards:

-

Your speed lathe should always be a good distance from the edge of the work bench

-

Stop the lathe before making any collet closer adjustments

-

Always make sure that the collet has a secure grip on the workpiece

For more information on any of these topics, its recommended checking with OSHA for maximum compliance. Once you fully understand the maintenance and safety precautions, using a speed lathe is all about what you can create!

Conclusion

Speed lathes are excellent and useful machines in an industrial workspace. They have been around for many years, and they’ll continue to remain a vital part of manufacturing operations.

However, like any machine, there are hazards and dangers that every user should be aware of to avoid injury. It’s vital to take note of all safety guidelines, such as:

-

Always wear protective eyewear, work boots, and removing any jewelry

-

Become familiar with the emergency stop switch and safe operational procedures

-

Keep the lathe dust-free and out of extreme hot or cold temperatures

-

Check the lathe for loose parts before operating

-

Handle other tools carefully when the lathe is on

As long as you are a certified operator who understands the safety requirements and the operation of a speed lathe, you should have no problems at all. Always make sure that you and your crew’s safety comes first for a smooth operation.

WARNING: This product can expose you to chemicals which are known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to

WARNING: This product can expose you to chemicals which are known to the State of California to cause cancer and birth defects or other reproductive harm. For more information go to